How to start a jam – jelly producing unit? Know about step-by-step production phases, including fruit preparation and packaging

India is the second-largest producer of fruits and vegetables in the world Total area under horticulture crops is approximately 28 million hectares with a production of 355 million tonnes in 2022-2023, Out of which 97.97 million tonnes of fruit crop production during the year 2018-2019 As per CIPHET (Central Institute of Post-Harvest Engineering and Technology) data, 18% of India’s fruit and vegetable production, which is approximately valued at Rs 13,300 crore, is wasted annually due to post-harvest management and only 2% of the horticultural crops being used in value-added products

India has 15 agro-climatic conditions, 72 subzones, six seasons, diverse soil types, and plentiful precipitation. Because of this, our nation is a producer of high-quality green produce. Organic products are an important wellspring of energy for individuals they are short-lived. We are ready to add several items that may have a longer period of usability.

In the whole food handling industry, jam and jelly are the most well-known items that we can produce without any problem. It needs the least machinery. Thus, the fixed capital cost is so less. Indeed, you have effectively a regular place of employment, so you can think about this business to begin. Likewise, you can produce different items, including natural product bars, juice, sauce, and pickles, from a similar unit.

This article incorporates an itemized jam jelly-making business project test with machinery, cost, and crude materials. Likewise, it contains important contributions to beginning a jam jelly creation business with little speculation.

10 Steps in starting a jam and jelly production business

STEP 1: Understand the difference between jam and jelly

Jam and jelly are two unique items with various attributes and creation measures as well. In any case, the items also have similarities. Both jam and jelly are made with fruits or fruit segments. Along these lines, you should comprehend the items appropriately first.

JAM | JELLY |

Jam contains both sugar and pectin. It contrasts, nonetheless, in that genuine, squashed fruit or fruit mash is utilized rather than fruit juice. The squashed fruit is cooked down, for the most part with a touch of corrosive, until the fruit loses its shape and consistency. At that point, sugar and pectin are added to the combination.

Once cooled, the jam takes on a clear quality. Light goes through it, yet obvious pieces of fruit are suspended all through.

In light of jam’s incorporation of genuine fruit rather than juice, it might seem like the more beneficial alternative of the two. In any case, to qualify as a jam under the U.S. Food and Drug Administration (FDA) rules, an item should in any case contain over 55% sugar. Sugar is considered a preservative agent in every blend, drawing out moisture from the fruit. |

Jelly is sweet, it is firm, smooth, and gelatinous. Jelly is made up of cooked, clarified fruit juice, sugar, and pectin; it does not contain enough naturally occurring pectin like jams. In the wake of cooking, before it has had the opportunity to cool, the blend is strained through a fine work jelly pack to eliminate contaminants and solids.

Whenever it has cooled and cemented or solidified, you are left with a firm, straightforward fruit spread. Jelly is prominent for its thick gel, its gemstone-like clearness, and for the way that it is made with fruit juice rather than fruit.

|

STEP 2: Market Analysis

Jam and jelly are important food items as they upgrade the agreeability of food because of its taste and flavor. As they contain fruits, they supplement the food with nutrients and minerals. Henceforth, these items have generally excellent market potential.

The greater part of the families, cafés, different diners, clubs, lodgings, and so forth devour jam and jelly consistently. Also, these are the significant selling items in numerous outlets like staple shops, departmental stores, and so forth. Furthermore, the interest in jam and jelly is developing seemingly endless amounts of time after year.

In the Indian market, you will discover a great deal of set up brands as Smucker Kissan, Druk, Tops, Cremica, Patanjali, and so on. Be that as it may, the market is overwhelmingly for the little units delivering these items in the particular locale.

STEP 3: Prepare the Detailed Project Report

Setting up the business plan or project report is the initial step. Comprehensively, you have to make reference to the project diagram, business objective, specialized viewpoints, and project financial aspects, including cost and marketing plan. The specialized perspectives contain the crude material rundown, production process, and so on. Also, you should specify where you will secure the crude materials.

Jam-Jelly Making Sample Project Cost;

sample project cost of a 15-tonne jam and 15-tonne jelly production is as follows:

Particulars | Description (in Lacs ) |

Land | Own land |

Building and civil work | 7.25 |

Plant & Machinery | 8.20 |

Fixed Assets | 2.80 |

Pre -operative cost | 2.25 |

Contingency & Escalation | 1.20 |

Margin for Working Capital | 1.75 |

Total | 23.45 |

total cost is approximately 23.45 lacs with some variation

STEP 4: Marketing Strategy;

The marketing plan of the proposed project may incorporate promotional schemes like discount schemes, references, commercials, new product advancement, and so on. Also, you can think about the attractive packaging and tie-up with bulk purchasing houses like Hostels, restaurants, Canteens, etc

The adequacy of dissemination, inclusion, and practice is the key significance in accomplishing the ideal jam and jelly deals. Subsequently, understanding the dissemination directions is critical for the maker to plan and actualize a successful conveyance procedure. In this way, you should give additional emphasis on building a potential distribution channel.

Furthermore, you can pick up the market share through improving retailer, and wholesaler edges. At last, you can consider using the media like transmission, newspapers, and furthermore the informal community stages to present the items and furthermore attract more customers.

STEP 5: Business Registration and License ;

In our nation, starting a jam jelly-making business, even in little scale requires business registration. Aside from the sole proprietorship firm, you can enroll the association as an LLP or Pvt Ltd, or Ltd organization.

After enrolling in the business, you should check the necessary business licenses and authorizations. Contingent upon the area, you should get a Trade License. Apply for MSME Udyog Aadhaar enlistment on the web. Also, you should get the FSSAI enrollment. An FPO permit is important to begin a fruit preparation industry in India. As of now, GSTIN is a must in our nation for a business.

There is no significant contamination issue related to this industry aside from the removal of waste, Hence, you should oversee it fittingly. It is fitting that you apply for a “No Objection Certificate” from the State Pollution Control Board.

STEP 6: Arranging the Finance;

Presently, you should amass important money. On the off chance that you have your own capital, at that point you don’t need to take any credit. Be that as it may, you can apply for the whole project fund from the banks or other financial organizations. On the off chance that you have enough capital for the fixed cost, at that point you can also apply for working capital credit as an overdraft facility.

STEP 7: Establishing the Unit ;

Area choice is the most important perspective in setting up the unit. Also, you should consider the utilities that you need to work on the unit. You will need adequate water and power gracefully. By and large, the particular region requirement relies upon the unit size and creation yield of your project. Nonetheless, you can begin a small scope activity from 1000 Sq Ft of secured territory.

STEP 8: Procuring the Machinery

1 )Pulper Machine, 2) Slicing Machine, 3) Juice Extractor

4) Steam Jacketed Kettle 4) Blender/Grinder 5) Container Washing and Filling Machine 7) Baby Boiler 8) Sealing Machine 9) Stirrers, SS Utensils, Burner, Weighing Scales, Hand Gloves 10) Miscellaneous Tools and equipment 11)

Testing Equipment

STEP 9: Procurement of Raw Materials

To begin the business creation, you should obtain vital crude materials. The major consumables you require are fruits, sugar, gelatin, added substances, additives, food colors and so forth Also, you should acquire the packaging consumables like plastic jars, pockets, names, cardboard boxes for external pressing, and glue tapes.

STEP 10: Jam and Jelly Production Process

Commercial Jam Production Procedure

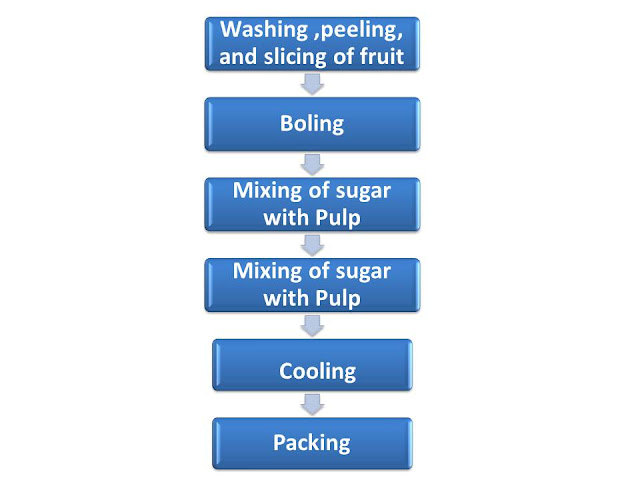

Firstly, wash the new fruits in water and peel the skin. At that point, cut or cut them into little pieces. Heat these pieces with water and blend a suitable amount of sugar into the mash. When the temperature is around 60°C, include citrus extract, shading, quintessence, and so forth At that point mix this blend for some time. After cooling, pack in the jugs.

The cycle stream diagram:

Commercial Jelly Production Procedure

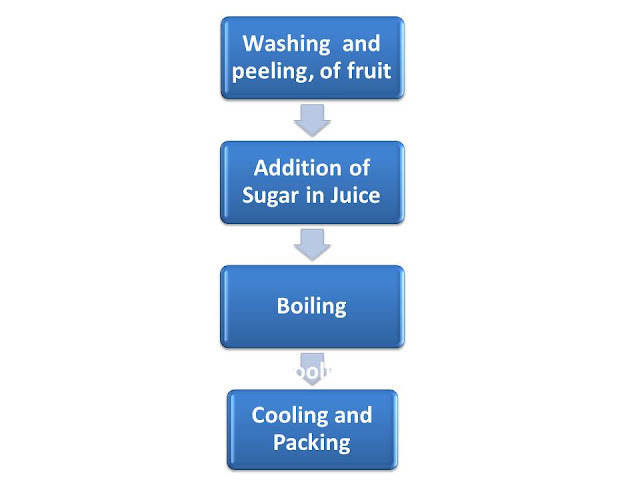

First of all, wash and strip the fruits. Feed them into the container of a juice extractor. In the wake of acquiring the juice, channel it. Certain fruits like rosella or guava need bubbling in water before removing the juice. add the sugar to the juice and heat this blend to change it into a jelly structure. Here, include gelatin, citrus extract, shading, and so forth in the necessary amount. Bubbling is done work jelly-like development is obtained. In the wake of cooling, pack the jelly.

The cycle stream outline:

In the business of jam jelly-making, you need to keep up the quality. Notice the assembling date, amount, MRP, and expiry date on the name