Jaggery (Gur) Making Process from the Sugar Cane Juice

Sugarcane is used for the preparation of three sweetening products, viz., white sugar (refined sugar), Khandsari (raw sugar), and Gur/Shakkar (jaggery). The manufacture of all three sweetening agents consists of extraction of juice from the cane and its clarification and concentration. Sugar and Khandsari is produced by the concentration of the juice by a vacuum pan system in small to big industrial units Jaggery is produced by an open pan system. It is a sort of cottage industry. The farmers also produce Gur for their domestic use. Cane juice is also used for human consumption, particularly during summer, as a substitute for soft drinks. As compared to soft drinks, it is more nutritious and cheaper. The shelf life of ready-to-serve cane juice can be increased to 4 months by a specific technique.

The composition of the jaggery

sucrose = 65%, glucose & fructose = 5 – 15%, protein = 0.4%, fat = 0.1 g, minerals = 0.6 to 1 gm. It also contains traces of vitamins and amino acids. 100 grams of jaggery provides 383 kcal of energy.

Health Benefits of Jaggery:

- Improve digestive health.

- Has a role in anemia prevention.

- Helps in liver detoxification.

- Helps in improving immune function.

- It works as a blood purifier.

- Helps in preventing respiratory problems.

- Relieves pain.

- Helps in weight loss.

- Good source of energy.

Making of Jaggery:

The production process of jaggery involves three steps:

1. Juice Extraction from Sugarcane

2. Filtration and Boiling

3. Cooling and Packing

Extraction of Juice

Fresh cane of good quality is crushed in a power crusher comprising of a set of three horizontally or vertically placed rollers to extract juice in a tank. By a good crusher, the juice extracted is about 60% of the cane weight.

Filtration & Boiling ;

It can be done by adopting the following methods —-

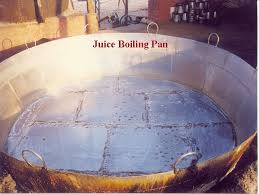

A) Single Pan Arrangement;

In the single-pan arrangement of jaggery making, operations of boiling, clarification, and concentration of juice are under in the same pan placed over a furnace specially designed for the purpose. In each batch, about 100 liters of juice is processed at a time. But the volume of the juice to be handled in a single batch can vary and will depend upon the size of the pan and furnace. For clarification, extracts of various plants (Sukhlai, okra, Masak Dana, phalsa, etc.) or certain chemicals (limewater, sodium carbonate, sodium bicarbonate, citric acid, potassium metabisulfite, etc.) are added when the juice starts boiling. The clarifier used coagulates colloidal non-sugars, including nitrogenous substances, which are then skimmed off. The juice is boiled extensively to concentrate it to 60° Brix. Addition of 1.3 g of sorbic acid to the semi-liquid hot Gur after removal from the furnace prevents deterioration of the quality of Gur, as it does not absorb moisture. The Gur is then transferred to a circular wooden or earthen platform (“chak’), air-cooled, and moulded into desired shapes and sizes. One batch yields about 10-15 kg of the product.

B) Triple Pan Arrangement ;

A triple pan arrangement is also employed for making jaggery. The triple pan arrangement is superior to a single pan because it allows better utilization of the heat of the fuel. The filtered juice is received in the first pan closest to the chimney of the furnace, and the heated juice is then transferred to the second pan, where it is boiled and clarified.

Addition of sodium bisulfite in the second pan @ 300 ppm would improve the colour of jaggery. It is concentrated to a Brix of 50° and then transferred to the third pan, which is located directly over the furnace, to build up Brix of 60° or more. The massecuite is then transferred to ‘chak’ and jaggery is made as in the single pan system. The output of one batch varies from 20-40 kg of jaggery.

FACTORS DETERMINING JAGGERY QUALITY:

The skill of a person to prepare jaggery of good quality is very important. Besides the skill of the person, the following factors influence the quality of jaggery.

Varieties

There is a large variation in the quality of jaggery obtained from different varieties, which is not necessarily attributable alone to differences in sucrose in the varieties. These differences can be due to the clarity of the juice as well. For good clarification, the varieties must have a low level of colloidal matter, minerals, and organic non-sugars such as harmful nitrogen, phenols, amino acids, starch, gums, etc., and a high level (300 ppm) of phosphate contents in juice. For Jaggery production, the state-wise recommended varieties are ———-

State | Verities |

Andhra Pradesh | Co 6907, CoT 8201, Co 8013, Co 62175, Co 7219, Co 8014, CoR 8001 |

Bihar | CoS 767, BO 91, Co 1148 |

Gujrat | CoC 671, Co 7527, Co 62175, Co 8014, Co 740 |

Haryana | Co7717, Co 1148, Co 1158, CoS 767 |

Karnataka | Co 7704, Co 62175, Co 8014, Co 8011, CoC 671, Co 86032 |

Madhya Pradesh | Co 775, Co 7314, Co 6304, Co 62175 |

Maharashtra | 775, Co 7219, CoC 671, Co 740, Co 7257, Co 86032 |

Orissa | Co 7704, Co 7219,Co 62175, Co 6304 |

Punjab | CoJ 64, Co 1148, CoJ 81 |

Rajasthan | 997, Co 419 |

Tamil Nadu | CoC 671, Co 62175, Co 7704,Co 6304, Co 8021, Co 86032, CoC 92061 |

Utter Pradesh | CoS 687, CoJ 64, Co1148, CoS 767, CoS 802, CoS 7918, Co 1158, CoS 8408, CoS 8432,BO 91, CoS 8315, CoS 8016, CoS 8118, CoS 8119, BO 19, CoS 837 |

West Bengal | CoJ 64, Co 1148 |

Fertilizer

The fertilizer application affects the jaggery quality greatly. High dose as well as late application of nitrogen increase the organic non-sugars (colloids, gums, pectin and non-protein nitrogen) and decrease the phosphorus content of juice, which affects the clarity of juice, resulting in dark-colored jaggery. Total organic acids increase and the pH of jaggery decreases due to high N application, leading to poor keeping quality and poor color of jaggery. Application of phosphorus to the crop improves the clarity of juice and also the quality of jaggery.

STORAGE OF JAGGERY

- The moisture content of jaggery plays an important role in maintaining its quality and sustaining its storage life. The higher the content of jaggery, the sooner the deterioration of jaggery quality during its storage. Therefore, before storing the jaggery, it should be well air-dried. The following points should be taken care of for the proper storage of jaggery.

- Store jaggery in godowns provided with moisture-absorbing agents like calcium chloride or quicklime. Use sugarcane trash, fly ash, paddy husk, etc., in between layers of jaggery bags. Jaggery should be stored in gunny bags lined with black polythene sheets or in airtight tins or glassware.

- Store jaggery before setting it in the monsoon at a low temperature (4–9 °C) in the storage room.